IT Solution for your industry

Digitalization Supports QA in Construction

5 Key Ways Digitalization Supports QA in Construction

In an industry where every decision matters and every minute can determine success or failure, digitalization in construction paves the way for faster, safer, and more profitable projects.

By implementing technology across all phases — from design and planning to execution and quality control — construction companies can completely transform their operations: reducing errors, optimizing resources, increasing transparency, and enhancing collaboration among all stakeholders.

Quality Assurance (QA), a critical pillar of project success, benefits enormously from this digital revolution. Specialized IT solutions allow real-time monitoring, complete documentation traceability, defect prevention, and faster delivery of compliant projects.

1. Real-Time Digital Inspections

What it brings:

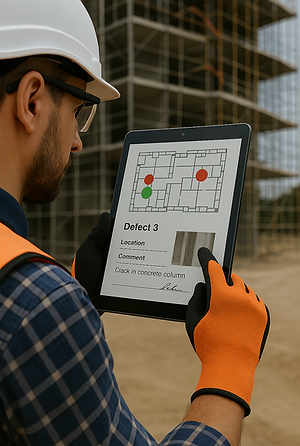

Replacing paper-based checklists with mobile applications for on-site inspections. Inspectors can record observations, photos, and signatures directly on tablets or smartphones.

Implementation:

• Use apps like Field View, PlanGrid, or SnagR.

• Customize inspection checklist templates.

• Train teams to work offline and sync data daily.

2. Complete Defect Traceability

What it brings:

Each defect is digitally logged, precisely located on digital plans, with photos and comments, and tracked until closure.

Implementation:

• Use QR codes or PIN locations on digital blueprints.

• Implement automated "punch list" reports.

3. Automated Inspection and Compliance Reports

What it brings:

Eliminates the need for manual report writing, reduces errors, and creates easily auditable records.

Implementation:

• Set up automated templates for daily, weekly, and final reports.

• Enable digital signatures for approval.

H4.4.eading 4

4. Photos/Video Documentation for Visual Evidence

What it brings:

Permanent visual documentation of progress and conformity/nonconformity at all project stages.

Implementation:

• Take photos at every inspection and upload them to the QA platform.

• Create standardized photo routes for critical works (e.g., sealing, concealed structures).

5. Automated Notifications and Workflow Management

What it brings:

Instant task assignments, defect notifications, and remediation requests sent directly to responsible parties.

Implementation:

• Configure automatic workflows for sending email or app notifications.

• Set deadlines and automated reminders.